Disposable Thermocol Glass Plate Machine / Foam Plate Making Machine with fast delivery

Disposable Thermocol Glass Plate Machine / Foam Plate Making Machine integrates forming and cutting at the same time, also the foam products could come out automatically

Product introduction

This type of developed by combining the domestic equipment and advantages, is a set of hydraulic pneumatic servo drive for an automatic forming cutting seek. Mainly by electrical components, Japan and Germany pump, ensure the reliability of the equipment operation, and can be used for hot forming process many kinds of plastic material, it can produce PSP, PE, all kinds of packaging products, materials used in food, medical supplies, electrical components, tourism products, toys, textile, etc.

Disposable Thermocol Glass Plate Machine / Foam Plate Making Machine the biggest advantage is forming cutting integration, reduce work link, produce the product directly, it can be collected in stacking area of work to save time, save the production base and greatly reduces the working intensity save artificially.

Advantage:

1. Suck and pull the food containers up. Even the containers don’t be sucked out successfully, this won’t affect next move.

2. There is one conveyor belt on each side of both can achieve automatically stacking, reduce labor intensity.

3. Disposable Thermocol Glass Plate Machine / Foam Plate Making Machine heater box separate into three parts, hydraulic cutting speed is faster, and use mechanical arms to suck products, all above methods reduce the whole working time.

4. Extend mold length, making the forming mold area larger and improving the production efficiency.

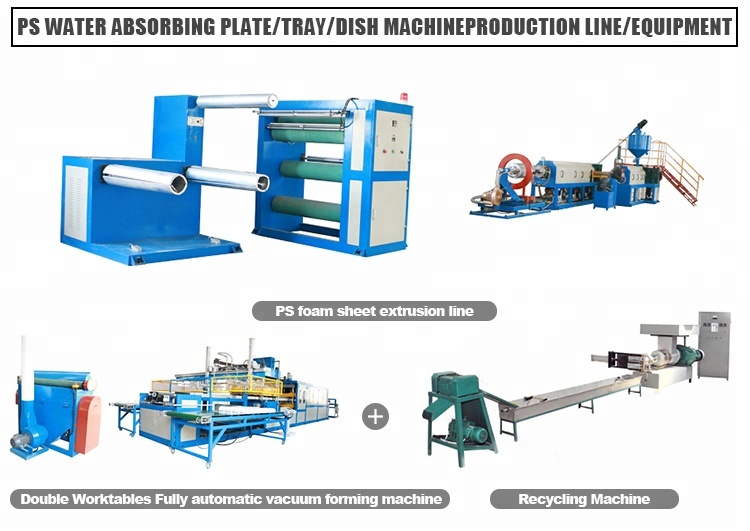

Disposable Thermocol Glass Plate Machine / Foam Plate Making Machine mainly including three main parts:

1. PS foam sheet extruder: make PS foam sheet from raw material

2. Double worktables fully automatic vacuum forming and cutting machine: make PS sheet to finished products, such as PS foam tray, PS foam box ,PS foam bowl etc (we can design mould according to customer requirements)

3.Recycle machine: recycle waste products to granules, the can mix with new material and put into PS foam sheet extruder again

Disposable Thermocol Glass Plate Machine / Foam Plate Making Machine Main technical parameters:

| Parameter | Unit | HY-1100 | HY-1250 | HY-1400 |

| Forming area | mm | 1100*1100 | 1100*1250 | 1100*1400 |

| Cutting off height | mm | 160 | 160 | 160 |

| Production efficiency | s/die | 3-6 | 3-6 | 3-6 |

| Installation dimension | m | 19*6*3 | 21*6*3 | 24*6*3 |

| Installation power | kw | 160 | 180 | 200 |

| Power supply | 3Phase 380v50HZ 3Phase 220v 60HZ | |||

PS foam sheet roll

PS foam plate,box,bowl

Disposable Thermocol Glass Plate Machine / Foam Plate Making Machine Associated Brands

Disposable Thermocol Glass Plate Machine / Foam Plate Making Machine Certifications

If you are interested in the product, contact 2bvideo.com for more information for more information

The information of 2bvideo.com limited shown above is provided by the user or collected on the network. Video 2B does not guarantee the authenticity,accuracy and legitimacy of 2bvideo.com limited information. Video 2B does not involve legal relationships and disputes between users arising from transactions other than secured transactions on this website. Disputes shall be settled by you through negotiation. If you are the person in charge or relevant employee of this enterprise, if you find that the enterprise information is incorrect or want to manage thiscompany, please contact us jacklee1558@gmail.com, after you claim the enterprise, you can obtain management permission, publish supplyand demand information, bring consulting orders, and remove page advertisements.

Main Product:

Foam Food Box Machine,

Foam Plate Making Machine,

PS Foam Sheet Extrusion Line ,

PS Foam Absorbent Tray Making Machine,

PS Foam Food Container Production Line,

Thermocol Plate Making Machine