Description of Hollow paddle dryer

Hollow Paddle Dryer is a horizontal stirring and heat conduction type drying equipment that can work continuously. Its stirring blade is like ship paddle, so it is called paddle dryer. In foreign countries, it is also called slot dryer or stirring dryer.

Hollow paddle dryer is successfully used in foodstuff, chemical, petrochemical, dyestuff, industry sludge fields, etc. The characters of heat transfer, cooling, and stirring make the machine can achieve the following operation: Calcination (low temperature), cooling, drying (solvent recovery), heating (melting), reaction and sterilization. Stirring paddle is heat transfer surface as well, it makes the unit efficient heat transfer area larger, and handling time is reduced. Heat transfer surface of wedge type has slef-cleaning function. Compress—expand stirring function makes the material mixed uniformly. Material makes piston flow movement along the axial direction, in the axial direction interval, the temperature, humidity and mixedness gradient is very low.

Structure of Hollow paddle dryer

Take double shafts type for example to introduce the structure (paddle dryers include single shaft, double shafts, and four shafts). It consists of W-shape shell with jacket, upper cover, two hollow shafts with paddles, covers of two ends, swivel joint, flexible metal tubing and transmission mechanism that including gears and chain wheel, etc.

The cores of the equipment are the two hollow shafts and the hollow paddles welded on the shafts. The shape of paddle is wedge-shape hollow hemicycle, inside it can be input heating medium. Except the stirring function, it also is the heat transfer device. Two main heat transfer surfaces of paddle are slope surfaces. When material contacts with the slope surface, granules will slip away from the slope surface with the rotary of paddle. It can make the heat transfer is renewed continuously, so the heat transfer is strengthened. At the triangle bottom of paddle there is scraper blade, it can sweep the material that deposits at the bottom, so it can avoid the dead corner.

There are some requirements for the distribution of paddle and the size of its each part. And at the feeding area, drying area and discharging area, there are not only paddles but also complementary unit, it can ensure the machine works stably, and dry uniformly. Moreover, residence time can be regulated.

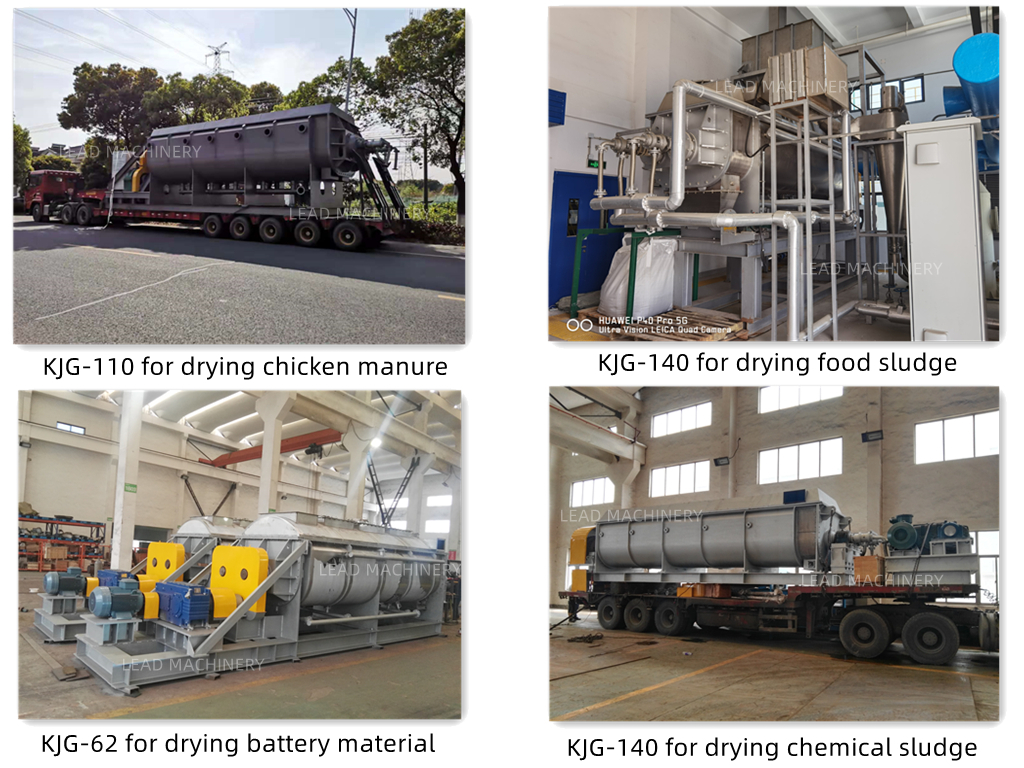

Application materials of hollow paddle dryer

Environmental protection industry: Sewage sludge, activated sludge, food sludge, oily sludge, textile dyeing sludge, chemical sludge, electroplating sludge, offscum of pharmaceutical factory, offscum of sugar factory, offscum of aginomoto factory, coal ash.

Organic fertilizer industry: Chicken manure, duck manure, pig manure, cow dung and so on.

Petrochemical industry: Polyolefin powder, high and low density polyethylene, linear low density polyethylene, polyacetal powder, nylon 6, nylon 66, nylon 12, cellulose acetate fiber, polyphenylene sulfide, allyl resin, engineering plastics, PVC, PVA, polrvinyl benzene, polypropylene, polyester, polyformaldehyde, styrene~acrylonitrile copolymerization, ethylene~propylene copolymerization

Feedstuff industry: Soy sauce offscum, bone matrix feed, distillers’ grains, heels of foodstuff, apple pomace, orange skin, bean pulp, chicken bone feed, fish powder, feed additive and chemical sludge.

Foodstuff industry: Starch, cocoa bean, niblet,

Chemical industry: Sodium carbonate, NPK compound fertilizer, kaolin, bentonite, carbon-white, conductex, phosphogypsum, oxidation sodium fluoride, lime nitrate, magnesium carbonate, sodium cyanide, calmogastrin, barium sulfate, annaline, calcium carbonate, dyestuff, molecular sieve, saponin.

Technical parameters of hollow paddle dryer

| Model |

Heat exchange area (m2) |

Power of motor (kW) |

Evaporation rate (kg/m2/h) |

Working temperature (℃) |

Rotary speed (rpm) |

Jacket working pressure (Mpa) |

| KJG-7 | 7 | 3 | 6~18 | 80~250 | 1~7 | 0.3~0.8 |

|

KJG-15 |

15 | 11 |

6~18 |

80~250 |

1~7 |

0.3~0.8 |

|

KJG-24 |

24 | 15 |

6~18 |

80~250 |

1~7 |

0.3~0.8 |

|

KJG-30 |

39 | 18.5 |

6~18 |

80~250 |

1~7 |

0.3~0.8 |

|

KJG-41 |

41 | 30 |

6~18 |

80~250 |

1~7 |

0.3~0.8 |

|

KJG-52 |

52 | 45 |

6~18 |

80~250 |

1~7 |

0.3~0.8 |

|

KJG-80 |

80 | 55 |

6~18 |

80~250 |

1~7 |

0.3~0.8 |

|

KJG-100 |

100 | 90 |

6~18 |

80~250 |

1~7 |

0.3~0.8 |

|

KJG-140 |

140 | 110 |

6~18 |

80~250 |

1~7 |

0.3~0.8 |

If you are interested in the product, contact 2bvideo.com for more information for more information

The information of 2bvideo.com limited shown above is provided by the user or collected on the network. Video 2B does not guarantee the authenticity,accuracy and legitimacy of 2bvideo.com limited information. Video 2B does not involve legal relationships and disputes between users arising from transactions other than secured transactions on this website. Disputes shall be settled by you through negotiation. If you are the person in charge or relevant employee of this enterprise, if you find that the enterprise information is incorrect or want to manage thiscompany, please contact us jacklee1558@gmail.com, after you claim the enterprise, you can obtain management permission, publish supplyand demand information, bring consulting orders, and remove page advertisements.

Main Product:

Roller Compactor,

Fluid Bed Dryer,

Spray Dryer,

Fluid Bed Granulator,

High Shear Mixer ,

Brushless DC Motor