item | value |

Brand Name | Cang Hai |

Condition | New |

Warranty | 1 Year |

Applicable Industries | Manufacturing Plant, Printing Shops, Advertising Company, corrugated carton making industry |

After Warranty Service | Video technical support, Online support, Spare parts, Field maintenance and repair service |

Local Service Location | Viet Nam, Mexico, Russia, Romania |

Showroom Location | Viet Nam, Mexico, Russia, Romania |

Video outgoing-inspection | Provided |

Machinery Test Report | Provided |

Marketing Type | New Product 2020 |

Warranty of core components | 1 Year |

Core Components | Gearbox, Pressure vessel, Pump, Gear, Bearing, Engine, Motor, PLC |

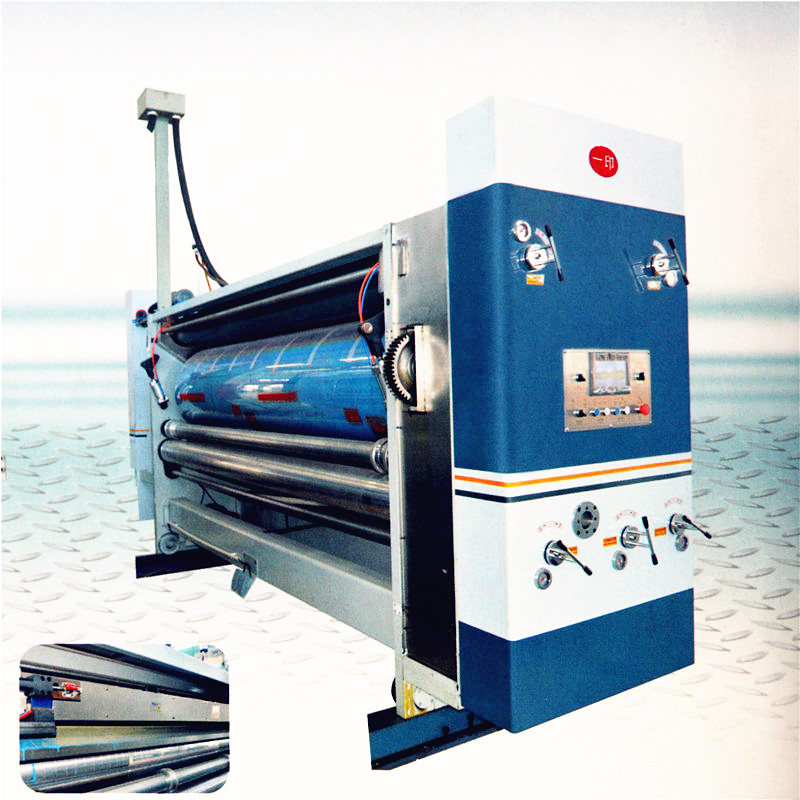

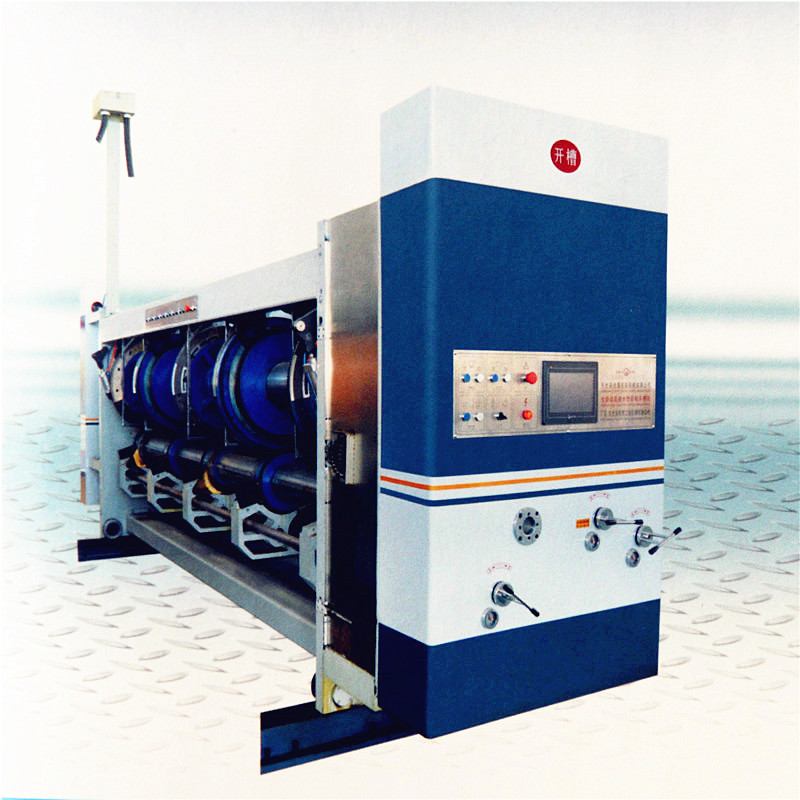

Type | automatic printer slotter die cutter |

After-sales Service Provided | Video technical support, Online support |

Key Selling Points | Automatic |

feature | high speed |

color | 3 colors |

Product name | Automatic High Speed High Definition Printing Machine |

Machine type | ZYKM 1020 |

Max machine speed | 220 pcs/min |

Max paper feeding size | 1000*2200 |

Max printing area | 950*2000 |

Max slotting depth | 250 |

Control system | PLC |

Registration precision | ≤±0.6(4 colors) |

If you are interested in the product, contact 2bvideo.com for more information for more information

The information of 2bvideo.com limited shown above is provided by the user or collected on the network. Video 2B does not guarantee the authenticity,accuracy and legitimacy of 2bvideo.com limited information. Video 2B does not involve legal relationships and disputes between users arising from transactions other than secured transactions on this website. Disputes shall be settled by you through negotiation. If you are the person in charge or relevant employee of this enterprise, if you find that the enterprise information is incorrect or want to manage thiscompany, please contact us jacklee1558@gmail.com, after you claim the enterprise, you can obtain management permission, publish supplyand demand information, bring consulting orders, and remove page advertisements.

Main Product:

Carton box making machinery,

carton box folder gluer machine,

Flat bed die cutting machine,

Flexo printing slotting die cutting machine,

Stitching machine,

corrugated cardboard production line