Are all micro submersible pumps brushless?

Not all micro submersible pumps are brushless. Submersible pump motors are available in both brushed and brushless versions. The main difference between the two is the working principle: brushed motors require carbon brushes to generate rotational force when working, while brushless motors achieve rotation through an internal electronic control system.

Brushless motors have the advantages of long life, strong anti-interference ability, high efficiency, low noise, and simple maintenance, so most submersible pump motors use brushless motors. However, brushed motors also have their applications in certain specific environments, such as heavy-load working environments, such as mud delivery to the bottom of sewage treatment plants.

How to distinguish between micro brushless submersible pumps and micro brush submersible pumps?

The main differences between micro brushless submersible pumps and micro brush submersible pumps are reflected in the following aspects:

1. Working principle: Micro brushless submersible pumps use electronic commutation, where the coil does not move while the magnetic poles rotate. In contrast, micro brush submersible pumps use mechanical commutation, where the magnetic poles remain stationary while the coils rotate.

2. Structure: Structurally, brushless submersible pumps do not have commutators and brushes, which makes their structure relatively simple. Brush submersible pumps contain two components: commutators and brushes.

3. Performance characteristics: Brushless submersible pumps have the advantages of high efficiency and energy saving, small size, low power consumption, and high efficiency. Due to the brushless design, it avoids the problem of carbon brush wear that may exist in traditional brush motors, thereby extending the service life and reducing maintenance costs. Brush submersible pumps, due to their working principle and structural characteristics, may have specific advantages in certain specific applications, such as heavy load working environments.

Submersible pump image

In which application scenarios can micro brushless submersible pumps and micro brush submersible pumps not be used interchangeably?

First of all, for equipment that requires frequent starting and braking, a micro brush submersible pump may be more suitable. Due to its large starting torque, low vibration, low noise, and high control accuracy, brush submersible pumps perform better in environments that require frequent operation. For example, in some agricultural irrigation systems that require periodic water supply, brush submersible pumps can better meet the demand for timed and quantitative water supply.

On the contrary, micro brushless submersible pumps are more suitable for installation on equipment that does not require frequent starting and braking, especially when the equipment needs to run smoothly for a long time. With its high efficiency and energy saving, long life, and low noise, brushless submersible pumps perform well in occasions that require continuous water supply and good mute effect. For example, in household water supply systems, brushless submersible pumps can provide stable and energy-saving water supply services; in garden water features such as fountains and artificial lakes, the low noise characteristics of brushless submersible pumps make them an ideal choice.

Technical Specification

| Model | DQB421-SB-7 | Voltage | DC12V |

| Current |

290mA |

Flow | 120-150L/H |

| Noise |

38dB |

Lifespan | 10000 hours |

| Application |

Fish tank,car refrigerator,car hair dryer,humidifier,purifier |

Continuous work |

Yes |

Can the brushless small submersible pump run 24 hours a day?

The brushless dc submersible pump can achieve 24-hour continuous operation. This is mainly due to the characteristics of the brushless motor, such as the brushless motor has a longer life, higher efficiency and lower noise, and the advantage of not needing to frequently replace the carbon brushes. Therefore, the micro brushless submersible pump is more stable and reliable when working continuously.However, although the micro brushless submersible pump can work continuously for a long time, the following points should still be noted in actual applications:

1. Heat dissipation problem: Long-term continuous operation may cause the temperature of the pump body to rise, affecting the performance and life of the pump. Therefore, it is necessary to ensure that the working environment of the pump has good ventilation conditions to avoid overheating.

2. Water quality problem: Impurities and particulate matter in the water may cause wear or blockage of the parts inside the pump. Therefore, it is necessary to clean the pump

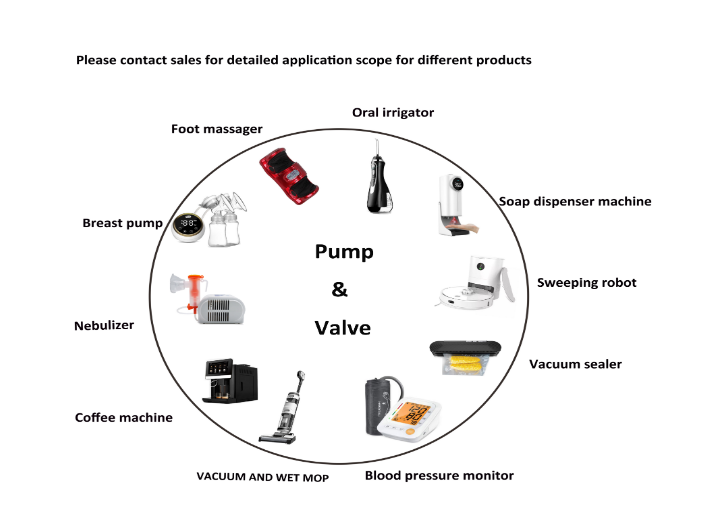

DYX Mini Pumps And Solenoid Valves Application

How is the life of a brushless electric submersible pump defined?

The life of a brushless micro submersible pump is usually defined by multiple dimensions, which cover key points such as the performance degradation of the pump, the increase in the failure rate, and the substandard performance due to wear or aging. Specifically:

1. Performance stability: The service life of a submersible pump is first reflected in the stability of its performance. Over time, the performance of the pump may gradually decay, such as reduced flow and reduced head. When these performance indicators are reduced to the point where they cannot meet the use requirements, it is generally believed that the service life of the pump is approaching the end.

2. Failure rate: The failure rate is another important indicator for measuring the service life of a submersible pump. As the use time increases, the various components of the pump may gradually wear or age, resulting in an increase in the failure rate. When the failure rate reaches a certain level and affects the normal use of the pump, it also indicates that the service life of the pump is limited.

3. Material aging and wear: The material of the submersible pump will age during long-term use, and the moving parts will gradually fail due to wear. These factors will lead to a decrease in pump performance or failure. Therefore, the durability and wear resistance of the material are also key factors affecting the life of the submersible pump.

DYX DQB421-SB-7 12v dc submersible water pump lifespan is more than 10000 hours .If you are interested in the product, contact 2bvideo.com for more information for more information

The information of 2bvideo.com limited shown above is provided by the user or collected on the network. Video 2B does not guarantee the authenticity,accuracy and legitimacy of 2bvideo.com limited information. Video 2B does not involve legal relationships and disputes between users arising from transactions other than secured transactions on this website. Disputes shall be settled by you through negotiation. If you are the person in charge or relevant employee of this enterprise, if you find that the enterprise information is incorrect or want to manage thiscompany, please contact us jacklee1558@gmail.com, after you claim the enterprise, you can obtain management permission, publish supplyand demand information, bring consulting orders, and remove page advertisements.

Main Product:

Mini Diaphragm Pump,

Solenoid Pump,

Peristaltic Pump ,

Piston Pump,

Solenoid Valve,

Solution For Mini Pumps And Valves