Gas-liquid coalescence filter is used to separate small liquid drop from gas by capturing, coalescing and discharging. Filter is made of various filter material and each filter material has different functions.

Liquid-liquid coalescence filter is made of a special layer, by using hydrophilia function of material surface to separate liquid. When medium passing through coalescing layer, particles will be absorbed on the fiber surface, and small liquid drop will be combined, coalesced together, to become a big liquid drop. When the liquid drop is big enough, it will be dropping from the surface by the effect of gravity and continuous medium. By that way, different liquid will be separated. For special service, separation filter can be considered for better performance.

The function of Liquid-liquid separation filter is by using the difference in the tension value of the surface of the material to the different components of the medium to block the droplets of the disperse phase falling off from the coalescer through, and the continuous-phase liquid can pass smoothly thereby achieving the secondary of different components. Usually, it can be used along with coalescence filter.

II. Filter Material

Coalescence filters made of non-metal composite material, metal filter material can be used for special service

Separation filters made of metal material after special treatment, other materials on request

III. Application

Gas-liquid coalescence filter is used for various gas drying, to separate misty liquid from the gas, such as gas-liquid separation after air compressor amine or glycol extraction tower, air compressor lubricant oil in fuel oil factory and chemical industry. Besides it can also be applied for dry gas sealing device from compressor inside, guarantee compressor running stably.

Liquid-liquid coalescence filter is used for the separation of liquid-liquid mixtures (non-miscible) with a certain difference in specific gravity, such as separation of water from gasoline aviation fuel and diesel oil, separation of oil from quench water, and separation of amines from liquefied petroleum gas.

IV. Characteristics

The coalescing process of the coalescence filter element is dynamic and stable state which can continuously filter the working medium

The coalescence effect is good after special treatment on filter material combination, which can effectively remove the dispersed phase

Different proposal will be selected according to different service to get the better effect

V. Technical Parameter

Gas-liquid coalescence filter

Filter precision:99.999% for 0.3μm

Max. differential pressure resistance: 0.5MPa

Max. heat resistance: 120°C

Liquid-liquid coalescence filter

Filter precision: within 30ppm(max.) according to different service

Max. differential pressure resistance:0.35MPa

Max. heat resistance: 150°C

If you are interested in the product, contact 2bvideo.com for more information for more information

The information of 2bvideo.com limited shown above is provided by the user or collected on the network. Video 2B does not guarantee the authenticity,accuracy and legitimacy of 2bvideo.com limited information. Video 2B does not involve legal relationships and disputes between users arising from transactions other than secured transactions on this website. Disputes shall be settled by you through negotiation. If you are the person in charge or relevant employee of this enterprise, if you find that the enterprise information is incorrect or want to manage thiscompany, please contact us jacklee1558@gmail.com, after you claim the enterprise, you can obtain management permission, publish supplyand demand information, bring consulting orders, and remove page advertisements.

Main Product:

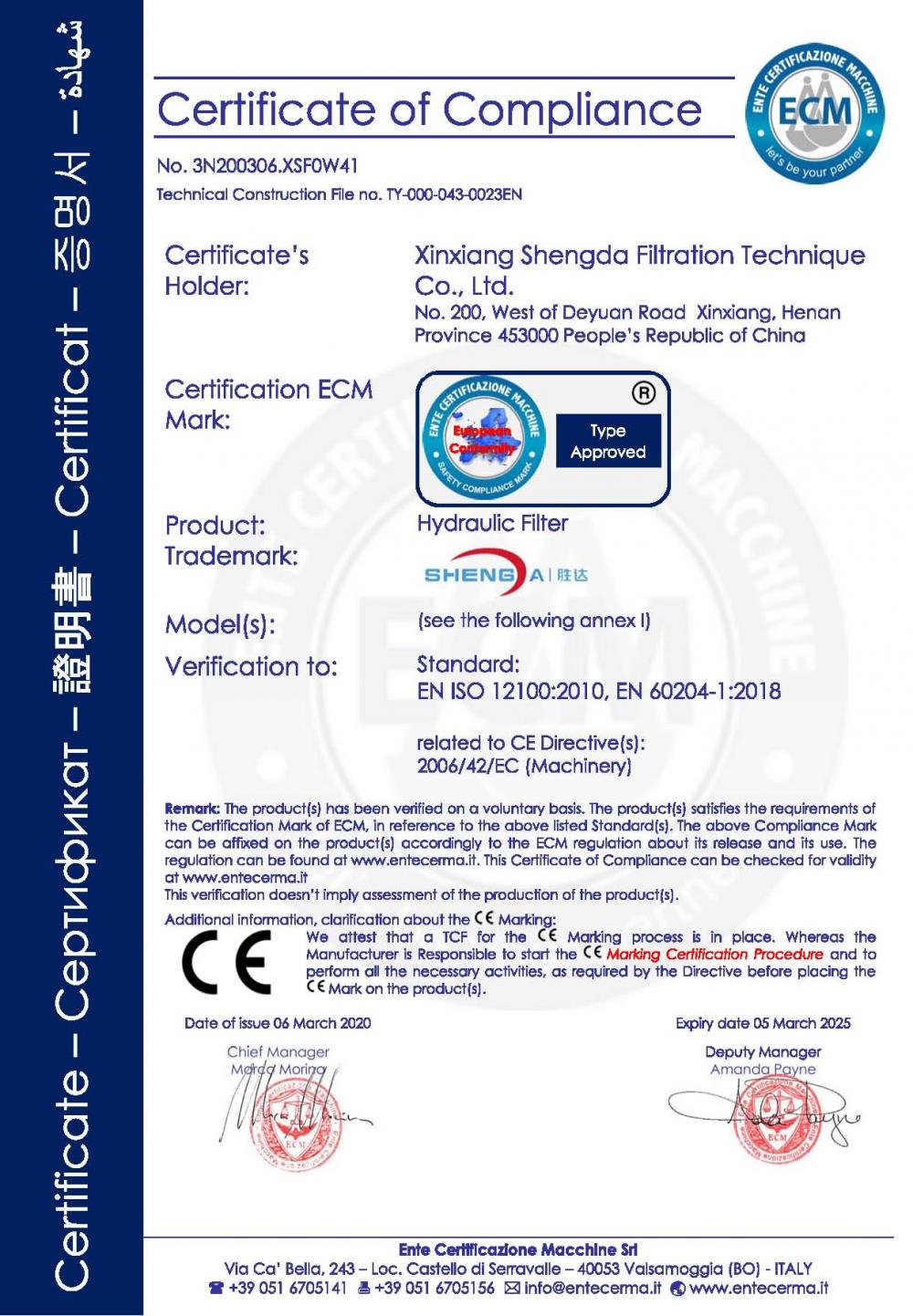

Hydraulic Filter,

Oil Filter Element,

Basket Filter Element ,

Johnson screen,

Polymer Filter Element,

Candle Filter Element