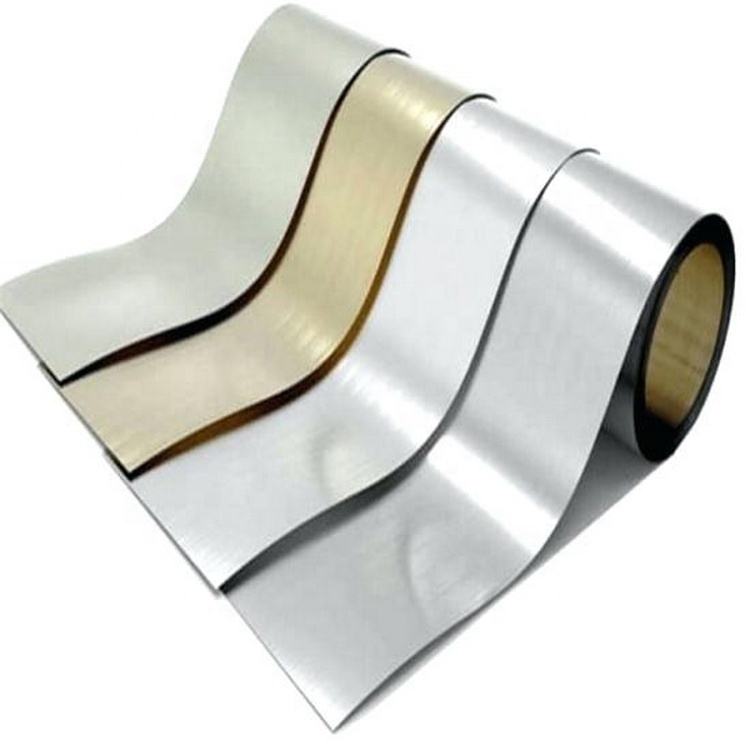

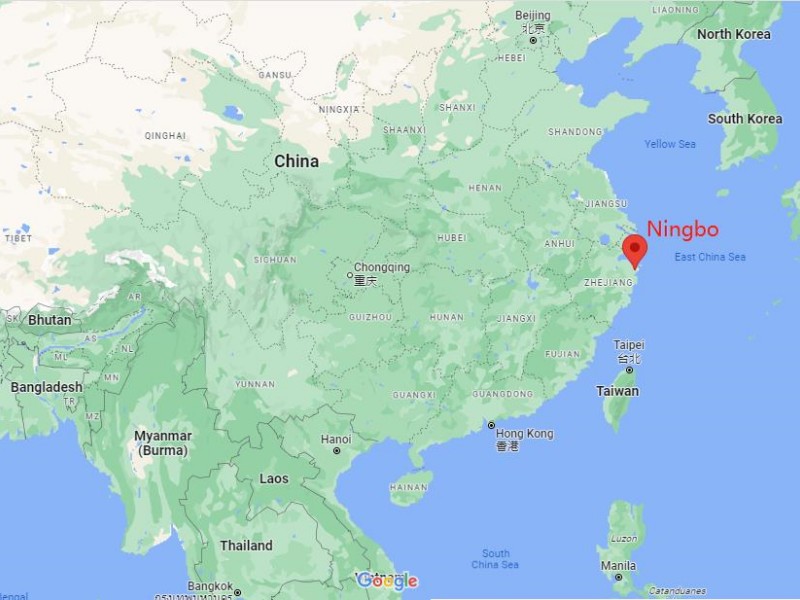

Ningbo boss metal had wide selection of cold rolled coil, strip and sheet products are available for a variety of use. These products come in heat and corrosion resistant forms. Their lightweight yet strong, durable and fully recyclable materials ensure versatility in application. The company boss metal is a national high-tech enterprise and undertakes projects under the National Torch Program. Since its establishment, it has placed great emphasis on improving production processes and developing technological equipment.

Food grade titanium refers to the grade of titanium that is safe for use in food preparation or consumption. This type of titanium is used in various food-related applications such as utensils, cookware, and other food processing equipment. It is known for its corrosion resistance, strength, and biocompatibility, making it safe for direct contact with food. It does not react with food, alter its taste, or leach any harmful substances.

Our workshop production line overview

The titanium pot, on the other hand, is an essential piece of cookware for outdoor enthusiasts. It is incredibly lightweight, making it easy to carry in a backpack. Despite its lightweight, it is extremely durable and can withstand high temperatures, making it perfect for cooking over a campfire. It also heats up quickly and evenly, ensuring that your food is cooked perfectly every time.

Cookware made from titanium material is becoming increasingly popular due to its numerous advantages. Titanium is a highly durable and lightweight material, making it perfect for outdoor activities such as camping and hiking. It is also non-toxic and safe for cooking, hence its use in cookware.

In conclusion, titanium is an excellent material for cookware and water bottles due to its durability, lightweight, and non-toxic properties. It is especially useful for outdoor activities, but it can also be used at home for everyday cooking and drinking.

| Part Name: | Stainless steel Titanium Strip / Foil / Tape / Coil, codl rolled | ||

| Specification: | Thickness and width as customer required | ||

| Surface condition | 2D,2B, BA,DF,1/2H, 3/4H,EH, H ....OEM as required | ||

| Allowable width Deviation | +/-0.15 mm | Standard | G/B,ASTM, DIN,JIS... |

| Brand code | Gr1(TA1),Gr2(TA2),Gr12(TA10) | 201,301,304,316,321,410S,430... | |

| Delivery time | Usually 7~15 days after payment | Shipment | By Express,Sea or Air... |

| Supply ability | 500+ tons per month | Mob/whatsapp/wechat +86-15824591272 | |

| Certification | IOS9001:2015,ISO/TS 16949:2009 | Process | cold rolled |

| Provided by : | Ningbo Boss metal | OEM | Yes |

| Packing method | Standard export packaging and also as customer's requirement. | ||

| Name | Superalloy Weld tube |

| Standard | ASTM B514,ASTM B515,ASTM B516,ASTM B517,ASTM B704 |

| Certification | IOS9001:2015,ISO/TS 16949:2009 |

| Outer diameter | 6.0-89.0mm |

| Wall thickness | 0.3-2.0mm |

| Material | INCOLOY840,INCOLOY800,INCOLOY825,INCONEL600/601,INCONEL625,HASTELLOY C276,BT840Mo,BT800Mo |

| Delivery time | Within 25 days after receiving deposit |

| Payment term | T/T,L/C |

| Supply ability | 15tons per month |

| Packing | Export standard package with polywood case or ISPM 15 stamped wooden case |

| Information | Beside the normal executive syandard.we could alse make the tubes according to your own requirements,such as wall thickness tolerance,hardness,surface requirements and etc.by different technical requirements and production technology,try our best to satisfied your. |

Professional and safe packing for export

At present, titanium alloy processing technology mainly includes CNC cutting grinding and 3D metal printing. Due to the characteristics of titanium alloy material, the processing links (forming, grinding and polishing) compared with aluminum alloy, the use of cutting grinding to process titanium alloy products has low yield, long time, large equipment demand and other difficulties. Taking the frame of the mobile phone as an example, according to Aibang polymer data, the overall yield of the frame of the titanium alloy mobile phone is about 30%-40%, far lower than the 80% of the aluminum alloy frame; And the processing time is long, about 3-4 times that of aluminum alloy. As a new direction for titanium alloy processing, metal 3D printing is based on the rapid manufacturing of three-dimensional models of parts, does not require special molds, applies powdered metal materials, and uses layer-by-layer printing methods to construct objects, which has the characteristics of high convenience, high precision and low cost. In addition, in the field of titanium alloy, hot isostatic pressing can effectively improve the mechanical properties of titanium alloy workpiece, reduce the cost of titanium alloy, improve production efficiency and material utilization.

If you are interested in the product, contact 2bvideo.com for more information for more information

The information of 2bvideo.com limited shown above is provided by the user or collected on the network. Video 2B does not guarantee the authenticity,accuracy and legitimacy of 2bvideo.com limited information. Video 2B does not involve legal relationships and disputes between users arising from transactions other than secured transactions on this website. Disputes shall be settled by you through negotiation. If you are the person in charge or relevant employee of this enterprise, if you find that the enterprise information is incorrect or want to manage thiscompany, please contact us jacklee1558@gmail.com, after you claim the enterprise, you can obtain management permission, publish supplyand demand information, bring consulting orders, and remove page advertisements.

Main Product:

Titanium foil ,

titanium strip,

metal material,

stainless steel strip,

stainless steel foil,

metal coil