3mm Blue Through-hole LED with 40 degree blue diffused lens:

This 304BD46D2L12 are the blue LED that with blue diffused lens. As we can see from the picture, this color of lens looks like the light water blue not the deep blue. Of course, if you need deep blue difussed lens for this 460nm - 470nm LED just feel free to let us know~ We can also produce it for you. On the other hand, during the production, we also produce this blue through-hole LED with 40 degree viewing angle, which can make sure it can light up more area. For the viewing angle, 20 degree 30 degree, 40 degree, 60 degree or 90 dgree are all available. Different viewing angle will emits different light spot, the more small degree, the small light spot and the long lighting distance. If you need some of this blue LED for your lighting project, just contact us for more detail about it~

3mm Blue LED with blue diffused lens Size:

Green Through-hole LED Features:

* Dimension of Lens: 3mm;

* Wavelength 460-465nm;

* Lens type: Blue diffused;

* High reliability and high radiation intersity;

Electrical Parameters:

| Parameter | Symbol | Rating | Unit |

| Power Dissipation | Pd | 60 | mW |

| Pulse Forward Current | IFP | 100 | mA |

| Forward Voltage | IF | 25 | mA |

| Reverse Voltage | VR | 5 | V |

| Junction Temperature |

Ti |

100 |

℃ |

| Operating Temperature |

Topr |

-40 ~ +80 |

℃ |

| Storage Temperature Range | Tstg | -40 ~ +80 |

℃ |

| Soldering Temperature | Tsol | 260 | ℃ |

| Electro-Static-Discharge(HBM) | ESD | 1000 | V |

| Service life under normal conditions | Time | 50000 | H |

|

Warranty |

Time | 2 | Years |

| Antistatic bag | Piece | 1000 | Bag |

* Pulse forward current condition: Duty 1% and pulse width=10us.

* Soldering condition: Soldering condition must be completed with 3 secongds at 260℃

Electrucal Optical Characteristics(Tc=25℃)

| Parameter | Sysmblo | Min | Typ | max | Unit | Test Conditin |

| Forward Voltage | VF | 2.7 | 3.0 | 3.4 | V | IF=20mA |

| Luminous Intensity | IV | 5300 |

|

6300 | mcd |

IF=20mA |

| Peak Wavelength |

λP |

|

462 |

|

nm |

IF=20mA |

| Dominant Wavelength |

λD |

460 | 465 | nm |

IF=20mA |

|

| Half Width |

△λ |

|

18 |

|

nm |

IF=20mA |

| Viewing Half Angle |

2θ1/2 |

|

40 |

|

deg |

IF=20mA |

| Reverse Current | IR |

|

|

5 | uA | VR=5V |

*Luminous Intensity is measured by ZWL600.

*θ1/2 is off-sxis angle at which the luminous intenity is half the axia luminous intensity;

Material of blue through-hole LED:

Application:

LED Beauty mask;

LED Back Light;

Manufacturing progress of through-hole LED:

Compare with SMD LED, through-hole LED production will be more complicated. Which means it will take more production progress and production time:

First of all, we need to prepare the LED chip(this will be same as SMD LED production); Secondly, we will need to put the LED chip into the LED frame, and then we will need the pure gold wire to connect the cathode and anode of LED frame. There comes different, For SMD LED production, we need to put the epoxy to LED frame and wait until it dry by oven. However, for LED Lamps, we need to inject epoxy into the mold of lens and put all the things to oven for at least 8 hours until they dry. After that, we need to tae them from the oven and get the LED out of mold. And then we need to cut the pins of LED so that they can be easy to test.

Finally, we got the LED. In order to make sure the quality and the uniform as good as required. We also need to put all the LED to the separation machine and them we will got the LED with same bins.

Storage Conditions:

1. avoid continued exposure to the condensing moisture environment and keep the product away from rapid transitions in ambient temperature;

2. LEDs should be stored with temperature ≤30℃ and relative humidity<60%℃;

3. Product in the original sealed package is recommended to be assembled within 72 hours of opening;

4. Product in opened package for more than a week should be baked for 6-8 hours at 85-10℃;

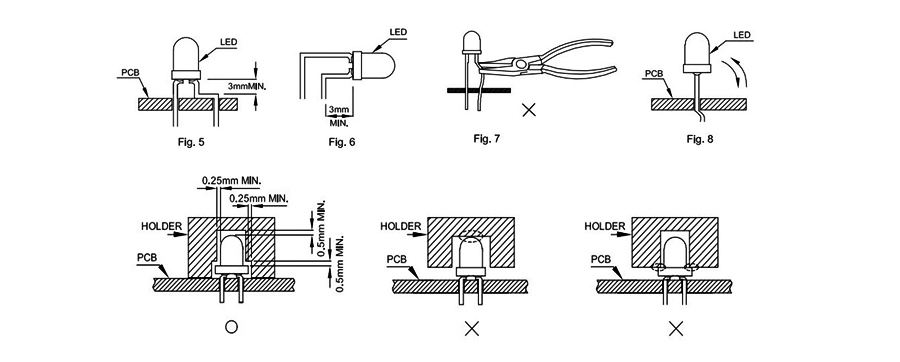

LED MOUNTING METHOD

1, The lead pitch of the LED must match the pitch of the mounting holes on the PCB during component placement;

Lead-forming may be required to insure the lead pitch matches the hole pitch;

Refer to the figure below for proper lead forming procedures;

Do not route PCB trace in the contact area between the leadframe and the PCB to prevent short-circuits;

Noted:

○ Correct mounting method;

× Incorrect mounting method;

2. When soldering wires to the LED, each wire joint should be separately insulated with heat-shrink tube to prevent short-circuit contact.

Do not bundle both wires in one heat shrink tube to avoid pinching the LED leads;

Pinching stress on the led leads may damage the internal structures and cause failure;

Noted:

○ Correct mounting method;

× Incorrect mounting method;

3. Use stand-offs(Fig 3)or spacers(Fig 4)to securely position the LED above the PCB;

4. Maintain a minimum of 3mm clearance between the base of the LED lens and the first lead bend (Fig. 5. Fig. 6)

5. During lead forming, use tools or jigs to hold the leads securely so that the bending force will not be transmitted to the LED lens and its internal structures;

Do not perform lead forming once the component has been mounted onto the PCB;

Lead Forming Procedures

1. Lead Forming Procedures;

2. Do not bend the leads more than twice (Fig. 7);

3. During soldering, component covers and holders should leave clearance to avoid placing damaging stress on the LED during soldering(Fig 8);

4. The tip of the soldering iron should never touch the lens epoxy;

5. Through-hole LEDs are incompatible with reflow soldering;

6. If the LED will undergo multiple soldering passes or face other processes where the part may be subjected to intense heat please check with Best LED for compatibility;

If you are interested in the product, contact 2bvideo.com for more information for more information

The information of 2bvideo.com limited shown above is provided by the user or collected on the network. Video 2B does not guarantee the authenticity,accuracy and legitimacy of 2bvideo.com limited information. Video 2B does not involve legal relationships and disputes between users arising from transactions other than secured transactions on this website. Disputes shall be settled by you through negotiation. If you are the person in charge or relevant employee of this enterprise, if you find that the enterprise information is incorrect or want to manage thiscompany, please contact us jacklee1558@gmail.com, after you claim the enterprise, you can obtain management permission, publish supplyand demand information, bring consulting orders, and remove page advertisements.

Main Product:

SMD LED ,

IR LED ,

Through-hole LED,

RGB LED ,

Flashing LED,

High-power LED