Explosion proof turbine flowmeter is an instrument used to measure fluid flow and can operate safely and reliably in environments with explosive hazards.

1、 Working principle

Turbine flowmeter is based on the principle of conservation of momentum. When fluid flows through turbine blades, it generates an impact force on the turbine, causing it to rotate. The higher the flow velocity of the fluid, the faster the rotation speed of the turbine. By installing sensors inside the flowmeter to detect the rotational speed of the turbine, the fluid flow rate can be obtained based on a certain conversion relationship.

2、 Explosion proof principle and form

Intrinsic safety type (Ex i) explosion-proof: This explosion-proof form restricts the energy in the circuit, so that electric sparks or thermal effects generated under normal operation or specified fault conditions cannot ignite the specified explosive gas environment. For explosion-proof turbine flow meters, their internal electronic components and circuit design meet the requirements of intrinsic safety, and even in the event of circuit failure, they will not generate enough energy to cause an explosion.

Explosion proof (Ex d): The explosion-proof shell can withstand the explosive pressure of the internal explosive gas mixture and prevent the internal explosion from spreading to the surrounding explosive gas mixture. The explosion-proof casing of the explosion-proof turbine flowmeter is like a sturdy "fortress". When an explosion occurs internally for some reason, the casing can confine the explosion inside, preventing flames and explosion impacts from affecting the surrounding hazardous environment.

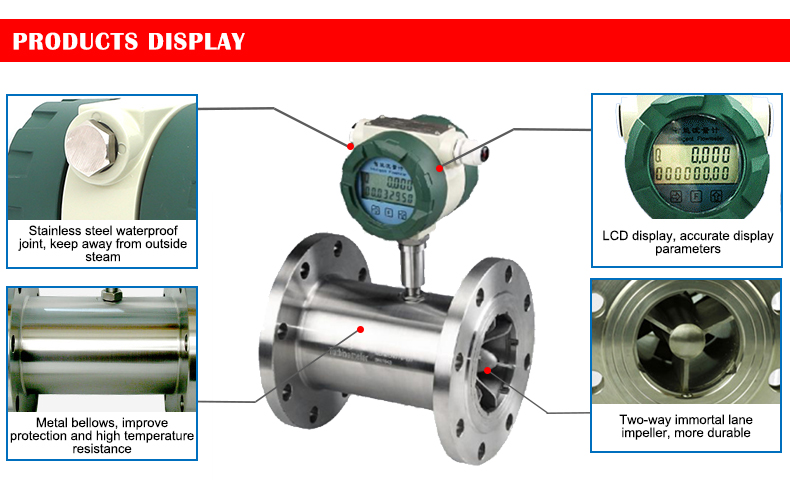

3、 Structural characteristics

Turbine components: Turbines are generally made of lightweight and high-strength materials, such as aluminum alloys, to ensure that the turbine can rotate sensitively under the propulsion of fluids, and has good corrosion resistance and mechanical performance.

Bearing system: A good bearing system is the key to ensuring smooth rotation of the turbine. High precision ball bearings or sliding bearings are usually used, and there are specialized lubrication and sealing measures to reduce friction and prevent fluid leakage during turbine rotation.

Sensors: Commonly used sensors include magneto electric, photoelectric, etc. Magnetic electric sensors obtain speed signals by detecting changes in the magnetic field during turbine rotation; The photoelectric sensor uses the obstruction or reflection of light to determine the speed of the turbine. These sensors have the characteristics of high precision and high reliability, and can work stably in complex industrial environments.

4、 Application Fields

Petrochemical industry: used in refineries, chemical plants and other places to measure the flow of crude oil, refined oil, various chemical raw materials and products (such as methanol, ethylene, etc.). Due to the presence of a large amount of flammable and explosive gases and liquids in these places, explosion-proof turbine flow meters can provide accurate flow data while ensuring safety, helping enterprises to carry out precise production control and material measurement.

Natural gas industry: used for flow measurement in the extraction, transportation, and distribution processes of natural gas. Natural gas is a flammable and explosive gas. Explosion proof turbine flow meters can accurately measure the flow rate of natural gas at wellhead, gas pipeline, refueling station and other locations, ensuring the safe and efficient transportation of natural gas.

Pharmaceutical industry: In the pharmaceutical process, explosion-proof turbine flow meters are also required for flow measurement of some organic solvents (such as ethanol, acetone, etc.) and pharmaceutical raw materials. These organic solvents are volatile and flammable, and explosion-proof measures are essential. Accurate flow control is also crucial for ensuring drug quality.

Our main products include electromagnetic flowmeter, turbine flowmeter,mass flowmeter, vortex street flowmeter, pressure transmitter, liquid level transmitter, and magnetic level indicator.