1.Basic Introduction

The filter element is mainly used to filter out the solid particles and colloidal substances in the working medium of the hydraulic system, effectively control the degree of pollution of the working medium, so as to protect the components of the hydraulic system from wear and damage, and extend the service life of the hydraulic system.

2.Material

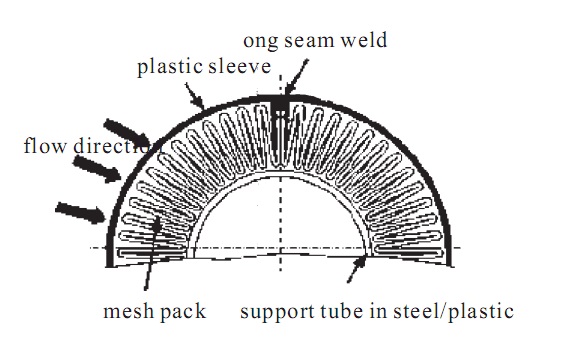

Stainless steel wire mesh filter elements are used in lubrication systems for bearings, water filtration, treatment plants for cooling emulsions and as guard filters. On the W and W/HC filter elements both the warp and weft are equally strong which results in uniform openings in the filter mesh. The pressure drop is lower when filtering with stainless steel wire mesh filter elements. The pleated stainless steel square mesh is supported in single or multiple layers.

Compared to W/HC elements, W elements have a smaller pleat depth. The W and W/HC stainless steel wire mesh elements are used in our return line and pressure filters.

3. Technical Parameter

Fiter precision: 3~ 200um

D Max. heat resistance: 150℃

Max. differential pressure resistance: 2MPa

Test standard

ISO2942-ISO16889-ISO3968-ISO3724-ISO3723-ISO2943-ISO2941

Applicable Test

| DIN ISO 2941 | Collapse Burst Pressure |

| DIN ISO 2943 | Material Compatibility with Fluids |

| ISO 3723 | End lost Test |

| ISO 3724 | Flow Fatigue Characteristics |

| ISO 3968 | Pressure Drop VS Flow Rate Test |

| ISO 16889 | Multi Pass Tes |

| ISO 2942 | Bubble Point Tst |

4. Advantages and Benefits

Composite structure, high filtration accuracy

Large dirt holding capacity long service life

High corrosion resistance and pressure resistance

Increased flow rate per unit area

High strength, easy to clean

5. Compatibility and Applications

● Hydraulic oils H to HLPO

●Lubrication oils DIN 51517,API,ACEA,DIN51515,ISO6743

●Compressor oils DIN51506

●Biodegradable operating fluids VDMA 24568 HETG, HEE, HEPG

●Non-flame operating fluids HFA, HFB, HFC and HFD

●Operating fluids with high water content(>50% water content) on request

It is widely used in petroleum, chemical, power plant, mining pharmaceutical, food, engineering machinery and other industries

6. Cleaning

The effectiveness of cleaning is heavily influenced by various factors:

● Filtration grade: The finer the filtration media, the poorer the cleaning performance tends to be.

● Working pressure: Higher operating pressures result in contamination particles becoming more securely embedded within the filtration media.

● Particle type: If contamination primarily comprises fibers, the cleaning effectiveness is inferior to that of contamination composed of cubic particles. Furthermore, it is important to recognize that each cleaning cycle can only restore approximately 80-90% of the original filter surface area. Consequently, after undergoing 4-5 cleaning cycles, the economic viability of further cleaning may no longer be justifiable (comparing cleaning costs to the service life of the filter).

If you are interested in the product, contact 2bvideo.com for more information for more information

The information of 2bvideo.com limited shown above is provided by the user or collected on the network. Video 2B does not guarantee the authenticity,accuracy and legitimacy of 2bvideo.com limited information. Video 2B does not involve legal relationships and disputes between users arising from transactions other than secured transactions on this website. Disputes shall be settled by you through negotiation. If you are the person in charge or relevant employee of this enterprise, if you find that the enterprise information is incorrect or want to manage thiscompany, please contact us jacklee1558@gmail.com, after you claim the enterprise, you can obtain management permission, publish supplyand demand information, bring consulting orders, and remove page advertisements.

Main Product:

Hydraulic Filter ,

Oil Filter Element,

Basket Filter Element,

Johnson screen,

Polymer Filter Element,

Candle Filter Element